Inspection of dünn leather manufacturing site - Daikoku-cho, Osaka.

The core of the dünn brand is the technology of thinning leather. I had the opportunity to visit the site.

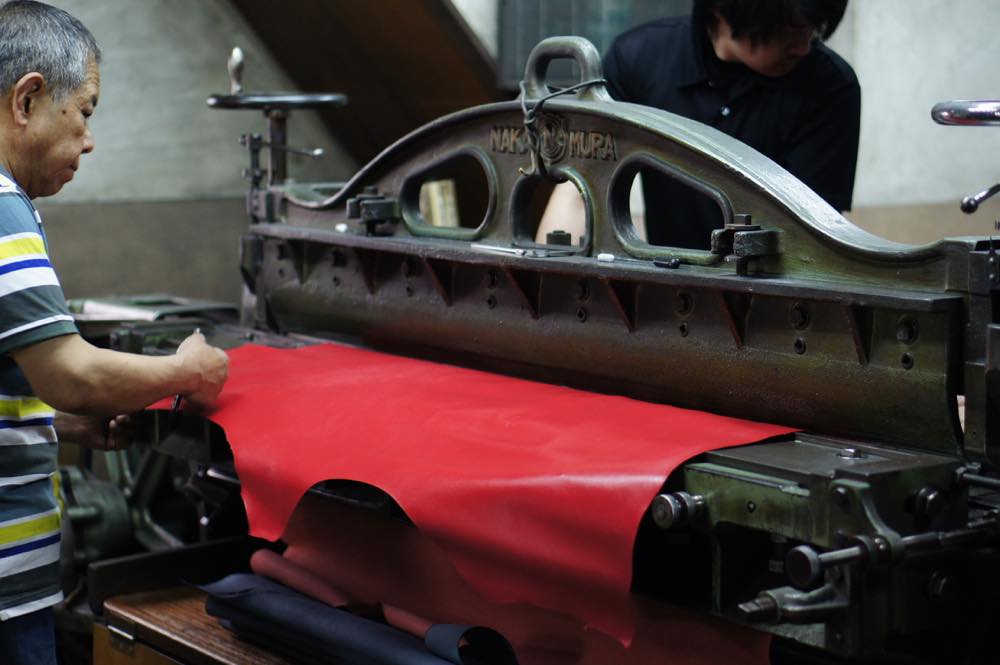

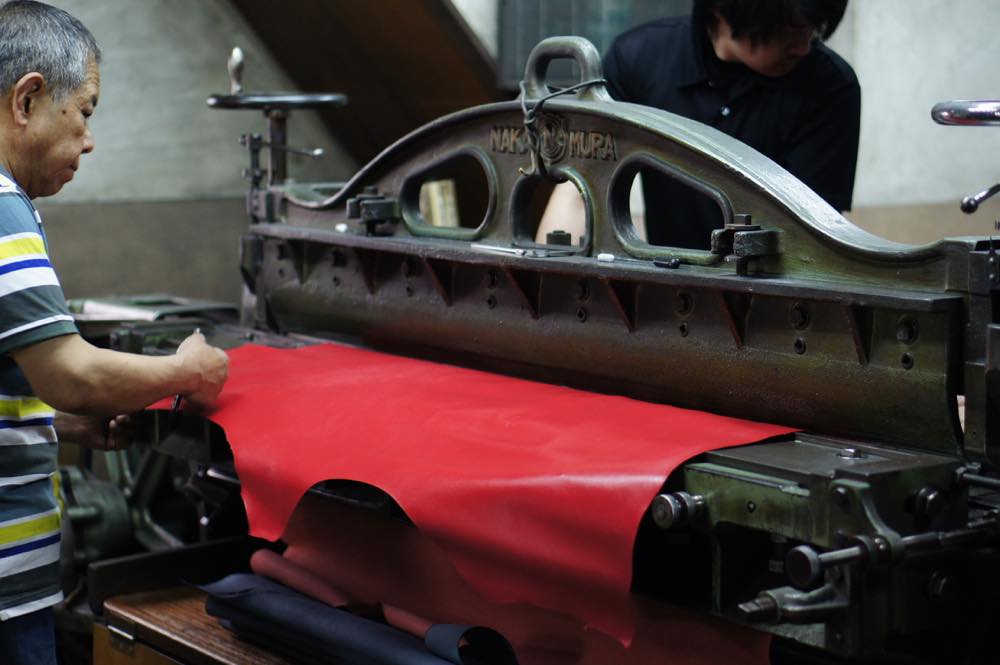

The leather used for dünn is made from a single piece that is thinly processed. Although small skiving machines are relatively easy to purchase and operate, skill is required to use such a large skiving machine and to perform the skiving process almost evenly.

As the roller-shaped blade rotates, the leather is skived and sharpened at the same time.

As the roller-shaped blade rotates, the leather is skived and sharpened at the same time.

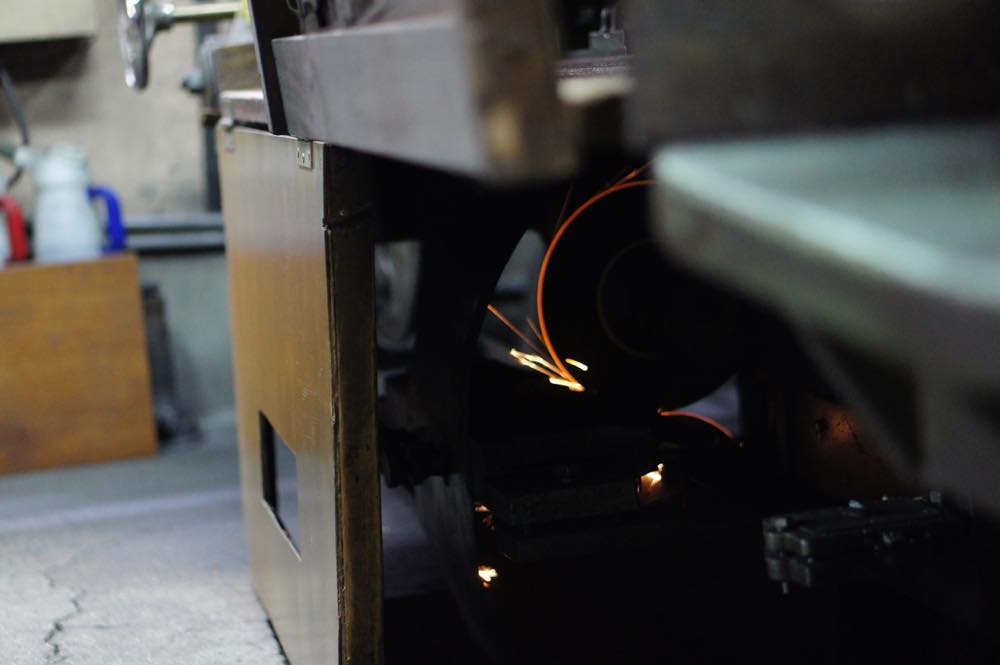

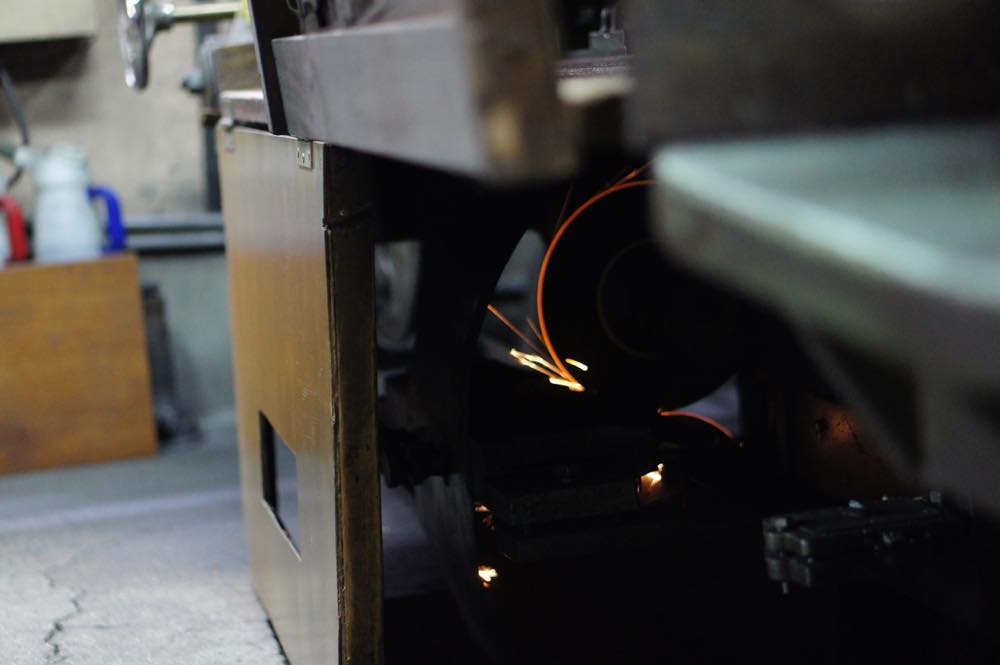

This is the roller blade.

When I checked the website of the manufacturer of the skiving machine , it seems that there is a distinction between processing a part of the leather as "leather skiving" and processing the whole leather as "sukiwari". There is also an explanation of something similar to this machine. The remaining leather with the silver surface removed. This leather is thicker than the leather used in dunn. At the moment, it looks like we have no choice but to recycle... I feel like I can make something.

Here is the pattern in progress. It seemed very quick to me, but since the leather is thin, they process it slowly. At first glance, the craftsmen's hands are light, so it looks easy at first glance, but it requires a very high level of skill to uniformly process large materials. Craftsmen who specialize in sukiwari and are highly skilled are valuable, so tanners all over the country seem to be constantly requesting their work. Our manufacturing is supported by the reliable techniques of Osaka craftsmen. After this, the thinly processed leather goes to the back processing process. Then, prepare a solvent made with a "secret combination". Actually, in the process mentioned earlier, when the blade is sharpened and strained, some iron powder will fly off, but it seems that it also contains an ``iron removal agent'' to lift the iron and remove it.

Then, prepare a solvent made with a "secret combination". Actually, in the process mentioned earlier, when the blade is sharpened and strained, some iron powder will fly off, but it seems that it also contains an ``iron removal agent'' to lift the iron and remove it.

In the general back processing process, there are very few environments in which it is possible to work with an entire sheet hanging at a 90 degree angle. This makes it possible to apply the solvent evenly.

In the general back processing process, there are very few environments in which it is possible to work with an entire sheet hanging at a 90 degree angle. This makes it possible to apply the solvent evenly.

It seems that various expressions can be created depending on the back processing. In addition to transparency, you can also create gradations with various colors. It expands your range of expression!

It seems that various expressions can be created depending on the back processing. In addition to transparency, you can also create gradations with various colors. It expands your range of expression!  Click here to see the actual work in progress. Seeing the manufacturing sites that are unique to Osaka, I felt a sense of mission as someone who also works in planning and development in Osaka to spread this technology to the world. Looks like you'll come up with a lot of ideas!

Click here to see the actual work in progress. Seeing the manufacturing sites that are unique to Osaka, I felt a sense of mission as someone who also works in planning and development in Osaka to spread this technology to the world. Looks like you'll come up with a lot of ideas!

Part 1: Straining process

The location is Daikoku-cho, Osaka. There are many companies related to leather and sewing products in the surrounding area.

The leather used for dünn is made from a single piece that is thinly processed. Although small skiving machines are relatively easy to purchase and operate, skill is required to use such a large skiving machine and to perform the skiving process almost evenly.

As the roller-shaped blade rotates, the leather is skived and sharpened at the same time.

As the roller-shaped blade rotates, the leather is skived and sharpened at the same time.

This is the roller blade.

When I checked the website of the manufacturer of the skiving machine , it seems that there is a distinction between processing a part of the leather as "leather skiving" and processing the whole leather as "sukiwari". There is also an explanation of something similar to this machine. The remaining leather with the silver surface removed. This leather is thicker than the leather used in dunn. At the moment, it looks like we have no choice but to recycle... I feel like I can make something.

Here is the pattern in progress. It seemed very quick to me, but since the leather is thin, they process it slowly. At first glance, the craftsmen's hands are light, so it looks easy at first glance, but it requires a very high level of skill to uniformly process large materials. Craftsmen who specialize in sukiwari and are highly skilled are valuable, so tanners all over the country seem to be constantly requesting their work. Our manufacturing is supported by the reliable techniques of Osaka craftsmen. After this, the thinly processed leather goes to the back processing process.

Part 2: Back processing process

Leather that has been thinned to a thickness of 0.4 to 0.6 mm through the sieving process. If left as is, it would be too soft and would not be suitable for molding products. As a countermeasure, we will treat the back side of the leather (floor surface). This is also a factory in Daikoku-cho with a very atmospheric atmosphere. First, nail the leather to the wood to hang it. Then, prepare a solvent made with a "secret combination". Actually, in the process mentioned earlier, when the blade is sharpened and strained, some iron powder will fly off, but it seems that it also contains an ``iron removal agent'' to lift the iron and remove it.

Then, prepare a solvent made with a "secret combination". Actually, in the process mentioned earlier, when the blade is sharpened and strained, some iron powder will fly off, but it seems that it also contains an ``iron removal agent'' to lift the iron and remove it.

In the general back processing process, there are very few environments in which it is possible to work with an entire sheet hanging at a 90 degree angle. This makes it possible to apply the solvent evenly.

In the general back processing process, there are very few environments in which it is possible to work with an entire sheet hanging at a 90 degree angle. This makes it possible to apply the solvent evenly.

It seems that various expressions can be created depending on the back processing. In addition to transparency, you can also create gradations with various colors. It expands your range of expression!

It seems that various expressions can be created depending on the back processing. In addition to transparency, you can also create gradations with various colors. It expands your range of expression!  Click here to see the actual work in progress. Seeing the manufacturing sites that are unique to Osaka, I felt a sense of mission as someone who also works in planning and development in Osaka to spread this technology to the world. Looks like you'll come up with a lot of ideas!

Click here to see the actual work in progress. Seeing the manufacturing sites that are unique to Osaka, I felt a sense of mission as someone who also works in planning and development in Osaka to spread this technology to the world. Looks like you'll come up with a lot of ideas!